The Austrian start-up Baubot is a specialist in automation solutions for the construction sector and thereby raising the level of innovation in this industry to new heights – for example with a robot solution for tunnel construction. Sensor technologies from SICK protect people and machines.

Robot colleagues now coming to construction

More and more strenuous, manual tasks are being performed by robots – in industrial environments at least. Up until now, this has not been the case in construction. If you compare the level of innovation in industry with that in the construction sector, great differences are evident. While even smaller industrial enterprises often invest in comprehensive automation solutions, things are usually still done more “casually” in construction. One reason for this is that the collaborative robots that are now increasingly often being used in industry have not been designed for use in construction. Power and mobility are needed here – that necessitates a corresponding safety concept, however, that quickly becomes a hindrance in construction.

Power, mobility and safety for the construction industry

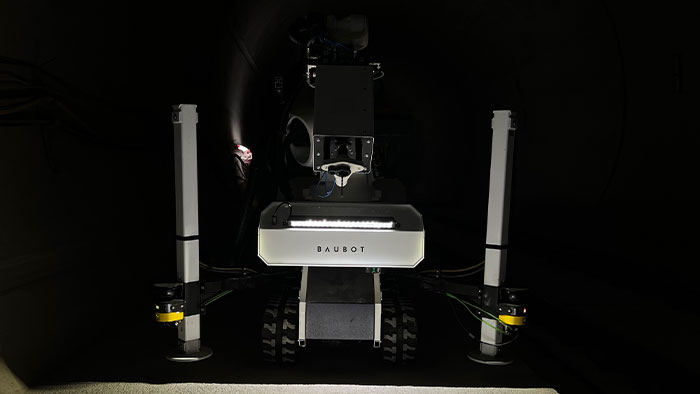

The Viennese start-up Baubot has specialized in these kinds of developments and offers complete solutions incorporating robots from KUKA and SICK sensor technology that satisfy the needs of the construction industry. The “Baubots” (construction bots) are equipped with sophisticated safety functions. Advanced sensors and collision detection systems ensure safe operation even in dynamic environments. This enables humans to work directly alongside mobile robots without having to make any compromises with regard to reliability or safety.

Wide variety of tasks

Victor Rodionov, COO of Baubot, explains the key tasks of the new construction robots and the three core areas of the company: “The first area is developing and constructing customer-specific robotic systems based on our two models: the MRS5 and MRS12. The MRS5 is somewhat smaller than the MRS12, has a shorter robot arm, and a lower payload. These “mechatronic colleagues” perform a diverse range of tasks on the construction site, from drilling to grinding and polishing, right through to welding or spraying.”

Software and control systems

The second core area of Baubot is developing the software and control systems that enable the robots to perform specific tasks automatically. Victor Rodionov: “A good example is drilling. The system comes with an end effector on the robot arm – this alone is not sufficient, however. Suitable software solutions are required here as well. There are also additional technical features, for example to control dust production so the dust can be extracted directly at the drill hole.”

Mission programs for construction

The third area at Baubot is the application software that includes all processes as a complete solution. The Baubot Planning and Simulation Environment (PSE), for example, supports quick graphical planning of the mission positions and driving paths for the mobile robotic system in a virtual environment. The software imports BIM files, Point Clouds, 3D CAD files as well as 2D drawings of the construction layouts directly into the 3D environment. Baubot PSE also features a built-in post-processor that converts virtual simulations into mission programs tailored specifically to the requirements on site.

More safety in construction

Construction sites are a dangerous environment – and have been for a long time. “Not much has really changed during the past 50 years when it comes to the processes in construction. The same or similar tools and planning methods are used in most areas these days as half a century ago. This is also reflected in the risk statistics that show that every employee has an accident every four days on average. This is unbelievable, even if it often only involves a minor injury. The special safety requirements placed on robots can lead to significant improvements in this area because adequate protection is unfortunately often not provided when performing manual everyday tasks. People also tend, over time, to become ‘overconfident’ and thereby careless,” explains Victor Rodionov. Especially interesting, according to Victor Rodionov, is that the “safety level” on the construction site increases significantly after deploying a Baubot. “The safety consulting services of the SICK experts also raised many interesting questions and issues for us which flowed into the development of the machine.” This made finding a solution significantly easier, and the result is that a controller with an integrated safety CPU now controls and monitors all work processes on the Baubot. A fully-integrated robotic system for construction – safety included!

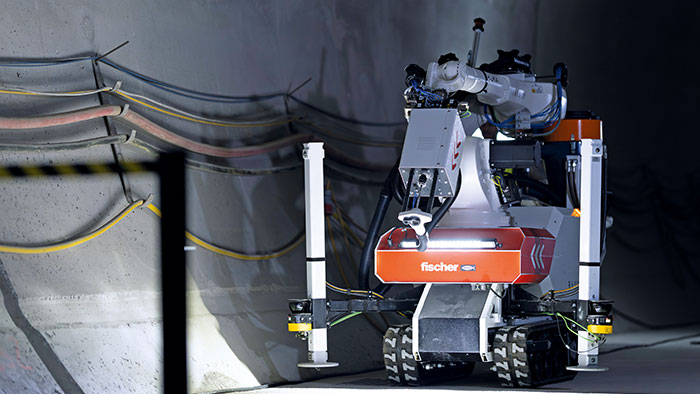

Drilling holes in the tunnel

One of the main tasks for the MRS12 Baubot is drilling holes. The robot requires no training or teaching in – based on its programming, it knows exactly where it needs to position itself when drilling. The work is carried out quickly and precisely as a result. There is no improvisation. Construction and drilling occurs exactly as planned and everything is documented, of course, because the system logs every work step. Additional inspections or the implementation of other logging mechanisms on site are therefore unnecessary.

Automation – not autonomy

A good example of the work the MRS12 Baubot performs in a tunnel is the installation of railings. A tunnel like the Koralm Tunnel, for example, has 30 kilometers of railings in each direction. Up to four holes for the brackets need to be drilled every half a meter. “We are not speaking here of a machine working autonomously and having to independently make decisions,” emphasizes Victor Rodionov. “We are focusing on automation, because we are not allowed to let the machines work autonomously due to statutory regulations, so there needs to be an employee with the device. This person, however, no longer has to perform the challenging work of drilling for 8 hours a day. The machine does the strenuous drilling work and the workers take care of the installation process,” explains the COO of Baubot. This is also well received by the employees on the construction site. While they were still skeptical of the robots at first, these days they are enthusiastic about them and are happy to have this kind of machine on their team. They don’t view the robot as a competitor, but rather as a tool.

Robot arm as hazard source

Another important hazard source is the movements of the robot arm itself, which could seriously injury a person. In the tunnel, the aim is to work with flexible safety fields that are continuously adjusted for the specific task / function of the robot. Rodionov: “On the construction site, we have different and constantly changing ambient and hazard situations that also take into consideration what the robot is currently doing. Different safety requirements and correspondingly wider or narrower safety fields apply when driving, aligning, drilling. Safety is always the top priority, but should not hinder the work.”

Laser excels

The robot needs to recognize whether a detected obstacle actually is one. For example, it needs to drive up suitably close to the wall to be drilled. It also has to keep an “eye” on the position of the employee at all times, of course. The laser sensors measure the distance by means of time-of-flight measurement. This makes them far superior to a camera system due to the often harsh ambient conditions. Ingo Wegscheider: “Conventional optical sensors are often not the best choice for dusty environments. Laser sensors also prove to be extremely reliable in outdoor applications, in particular when it is raining or snowing. Typical applications in the construction area include, for example, distance measurement when installing guardrails or railings on bridges.”