Manufacturing a tire requires over one hundred individual steps and a wide array of components - a complex process with high standards when it comes to quality and safety. Careful testing is absolutely essential as any undetected quality issues often result in complaints - which in turn result in added costs and potential damage to the tire manufacturers image. Thanks to powerful, industrial image processing technology in the form of IRIS-M, SICK offers companies a tailor-made system solution for designing cost-efficient quality control processes.

The more aspects of the complex tire manufacturing process that are monitored, the easier it is to guarantee the quality of the final product. Using manual monitoring for this purpose not only takes more time, it is also unreliable. Quality control systems based on powerful, industrial image processing can deliver reliable results. IRIS-M has been specially developed for this demanding task and is able to process both colors and 3D information. This data delivers reliable information about the shape and position of the tire - regardless of the characteristics of the background. This information is used to calculate something known as a region of interest, in which the system looks for markers. As a result, the system only evaluates markers that are actually on the tire. The main purpose of checks is to find out if any marks are damaged or missing completely. Color components also have to be identified and classified clearly. IRIS-M allows the individual markers to be evaluated - which markers are still valid and which ones are not.

Modular, pre-calibrated, user-friendly

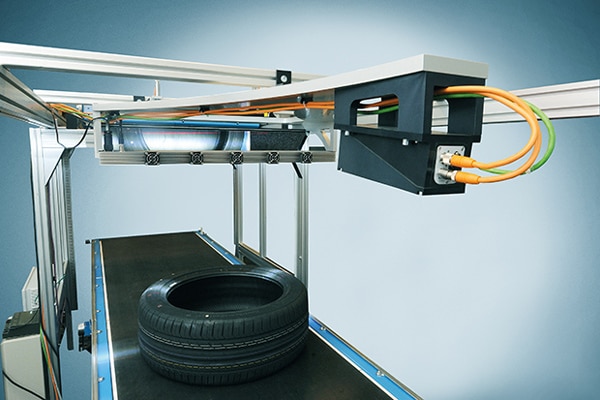

Depending on the requirements, the IRIS-M can consist of up to three standardized modules: Two identical modules - installed on top of and underneath the conveying system - detect and validate color markers and adhesive markers. The third line module is installed to the side of the conveying system and identifies the colored marks on the tires tread. All of the modules components (including the camera, laser, illumination, and mirror) are already calibrated upon delivery, based on the customers specifications. To take high availability requirements into account, the IRIS-M is equipped with a comprehensive range of diagnosis options and a self-test function. As soon as one of the components has to be cleaned or re-calibrated, a notification appears so that maintenance work can be organized in good time.

Image processing for complex vision Solutions

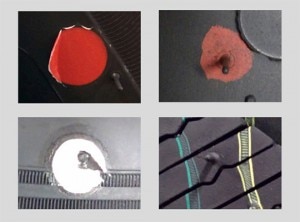

Red is not always red: one big challenge during image processing is identifying and validating various colored marks.

Red is not always red: one big challenge during image processing is identifying and validating various colored marks.

In addition to powerful vision components (the ColorRanger E streaming camera forms the heart of the system), the IRIS-M quality control system is also equipped with its own powerful image processing software, which is based on the HALCON image processing library. Because the system is required to clearly determine both the individual marks on the tire and their colors, the software has to deal with quite a complex challenge. This is because the color markings attached during the manufacturing process may change while the tire is in the curing press. Adhesive markers, on the other hand, are attached after the production process and can therefore be partially or even completely damaged during transportation. When identifying the marks on the tires treads, potential color deviations may also play an important role. Thanks to its powerful image processing capacity, the IRIS-M can classify so-called color areas and can also clearly assign any deviations to a color. Though it may be easy to the human eye, the IRIS-M has to use intelligent software algorithms for this task.

Whether it is identifying markers and/or marks on the tires treads, the IRIS-M can consist of up to 3 modules, depending on the requirements for the task and hand.

Whether it is identifying markers and/or marks on the tires treads, the IRIS-M can consist of up to 3 modules, depending on the requirements for the task and hand.

Scalable complete solution

Products, system knowledge, and years of experience in solving complex vision applications: With the IRIS-M, SICK brings all of this together to provide a scalable end-to-end solution for tire marking quality control. As well as a high level of performance, SICK also focuses on factors such as good cost efficiency and easy commissioning - important features for the wide acceptance and use of the system by international companies.

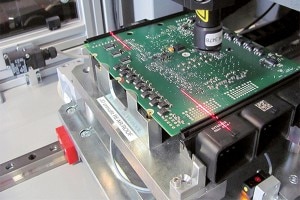

More information: Pin Inspector: one system, two quality checks  Plug connectors and printed circuit boards are some of the most cost-efficient electronic components - nevertheless, errors during the manufacturing and mounting of the components can have a huge impact. The Pin Inspector quality control system is based on the Ranger streaming camera and reliably checks that printed circuit board pins are in the right position before being pressed. Following the pressing process, the Pin Inspector checks the height of the pins. This information can be used to determine whether the pins have been pressed correctly onto the printed circuit board. This solution can also be used to Monitor individual plug connectors. Are all the pins in place? Have any of the pins been bent or broken off? Pin Inspector therefore offers two separate quality checks in a single system, which allows for easy modification and speedy integration into existing plants.

Plug connectors and printed circuit boards are some of the most cost-efficient electronic components - nevertheless, errors during the manufacturing and mounting of the components can have a huge impact. The Pin Inspector quality control system is based on the Ranger streaming camera and reliably checks that printed circuit board pins are in the right position before being pressed. Following the pressing process, the Pin Inspector checks the height of the pins. This information can be used to determine whether the pins have been pressed correctly onto the printed circuit board. This solution can also be used to Monitor individual plug connectors. Are all the pins in place? Have any of the pins been bent or broken off? Pin Inspector therefore offers two separate quality checks in a single system, which allows for easy modification and speedy integration into existing plants.