The longstanding collaboration between SICK and the Italian automation specialist TecnoFerrari is based on a common foundation: Being pioneers in matters of safety, and being able to master complex scenarios in doing so.

Successful partnership for ensuring the safety of mobile robots in production and logistics

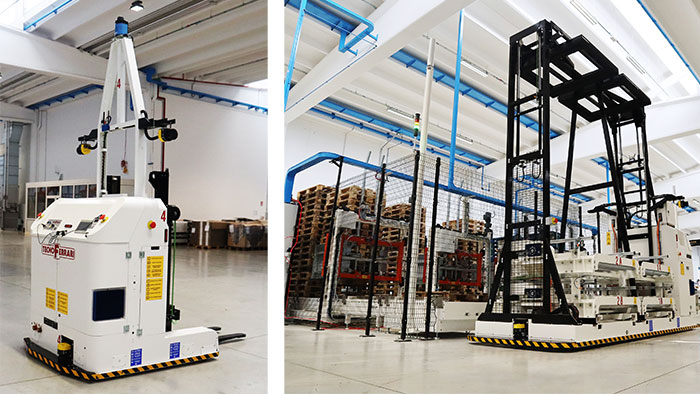

Gruppo TecnoFerrari S.p.A. develops complex systems for industrial automation. The company was founded in 1966 and has since made a name for itself, in particular in the ceramics industry, in the areas of warehousing, logistics and automation solutions for vision applications and end-of-line.

Complete safety for production employees

“We turned to SICK in order to be able to provide our customers with innovative automated mobile robots. This allows production employees to work alongside mobile robots in the same area, and work together without physical barriers and access controls in complete safety,” says Marco Fontana, manager of the Electronics department at TecnoFerrari.

Boosting productivity and flexibility

The use of mobile robots in the production and logistics areas has solved many challenges. It enables companies to boost the productivity and flexibility of their processes as well as increase safety because their use relieves the humans of tedious and repetitive tasks.

The high level of complexity in these environments, however, is also a serious challenge for safety. This aspect needs to be taken into consideration jointly with all partners in the early phase of planning the system.

Space-saving solutions using safety laser scanners

“We have for some years now also been developing complete solutions for customers working in areas other than the ceramics industry, e.g. in the automotive industry and the food and beverages industry. In these scenarios, the technologies used must be able to ensure extreme precision and reliability over a long period of time, and even under difficult conditions such as high temperatures, reflections or moisture,” says Fontana from TecnoFerrari and adds: “The compact size of SICK’s safety laser scanners gives us a great deal of freedom in selecting the right position for the scanners in our mobile robots. The Ethernet interface allows a space-saving solution using just a single cable. The added value for the customer is the space gained in the warehouse, which has a positive impact on the TCO (Total Cost of Ownership).”

Each device offers up to 128 freely configurable fields and up to 8 simultaneous protective fields. Furthermore, by using the Flexi Soft safety controller in combination with the safe motion control functionality, it is possible to dynamically adjust the relevant field. Finally, the Safety Designer tool enables configuration and commissioning to be completed in a matter of seconds.

A partnership with a future

Thanks to the knowledge and experience gained in numerous joint projects, the company is now also able to tackle complex installations. One example is an order from the automotive industry for which TecnoFerrari is employing 65 microScan3 safety laser scanners in combination with a package comprising Flexi Soft safety controller and Safe EFI-pro.

The partnership between SICK and TecnoFerrari, which has existed for 22 years, is constantly evolving and developing ever greater synergies. It enables the companies to jointly offer automation solutions geared towards safety, precision and reliability.

"We firmly believe in TecnoFerrari, in particular because of their focus on safety, which has grown so strongly along with the innovative spirit of the company in recent years,” says Gabriele Diana, Strategic Industry Manager in the Mobile Outdoor Automation business unit at SICK and adds: “We and TecnoFerrari share many common issues, in particular the central role of humans in automation. Both companies are family run. These common values have made TecnoFerrari a trusted partner of ours.”