The steel in electric arc furnaces bubbles in light orange hues. Flames blaze from the thin gap between the vessel and exhaust manifold; the heat is intense. This is what steelworkers unemotionally refer to as a “harsh environment” – but behind it are such extreme conditions for humans and devices that it takes special skills to master them. SICK has tried-and-tested solutions for exhaust gas measurement in electric arc furnaces – and for the no less intense monitoring of cement kilns – which serve to optimize processes. In addition to safety aspects with gas analysis and leakage monitoring, this means above all energy savings.

Measuring to the limit: How the “fire masters” from SICK save energy with exhaust gas analysis

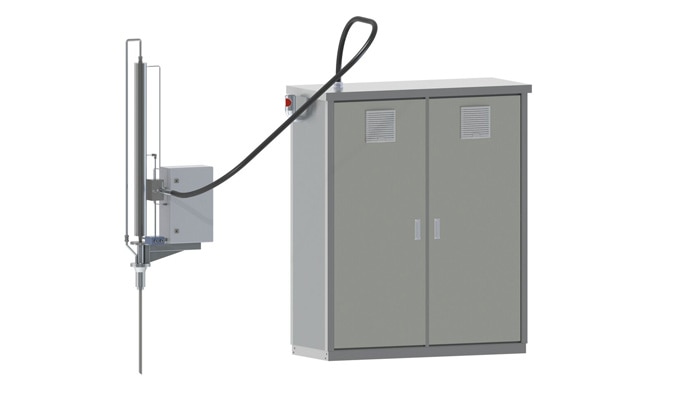

In the face of increasingly scarce resources, even small savings have great importance in heavy industry. The exhaust gas analysis technology from SICK is setting new benchmarks with fascinating solutions. In principle, the modern fire masters work with the elementary rules of combustion. Perfection, and therefore efficiency, are only achieved when the combustible components of the furnace exhaust gas burn free of residue and without waste. A campfire which smokes and crackles is not nearly as efficient as one which heats with a light flame. When monitoring furnace processes, SICK relies on this principle and analyzes all gases involved in the combustion for their composition. Perfect regulation of the gas compositions is subsequently achieved based on these measurements. The idea is the same for the steel and cement production. In both industries is the composition of gas atmospheres in furnaces a decisive factor for efficient function. However, due to the different circumstances for the process gas analyzer system METPAX300 for electric arc furnaces and the SCPS system for gas measurement directly in the rotary oven, measurements are done using different principles.

Efficient due to optimal combustion

Transparency plays an important role in the production of steel and cement for operating entities of electric arc furnaces and cement kilns. Permanent monitoring of the process ensures complete insight and overview and therefore ensures product quality. The data collected during gas analysis is the important basis for detecting incomplete combustion or the development of poisonous by-products and is thereby preventing their creation. This increases both safety and efficiency. In cement production, the temperatures are about 1,400 °C, and these reach up to 1,800 °C in steel production. To compare: The frictional heat of a spacecraft returning to the Earth atmosphere is right in the center at 1,600 °C. It’s no surprise that a correspondingly high amount of energy is expended for such extreme temperatures. A huge potential for savings.

Creating a safe process with sophistication and durability

Both systems used by SICK are characterized by the high level of durability corresponding to its usage sites. For example, the SCPS features rugged sample probes whose effective cleaning mechanisms prevent residue deposits and caking through targeted movements and rotations of the probes. This minimizes maintenance effort and secures the production process.

Dirty, difficult and dangerous – overcoming challenges

SICK is known for its huge portfolio of clean and intelligent solutions in factory and logistics automation. In process automation, on the other hand, things can get really hot. Insiders like to describe the conditions in a striking way as “dirty, difficult and dangerous” - the 3D business. But exactly in this field of challenging ambient conditions, SICK once again proves its own versatility and the ability to find new and innovative paths for and with the customer. The solutions for furnace process monitoring with the METPAX300 and the SCPS are an important testament that even the toughest conditions can be mastered. And this goes far beyond the initial installation. SICK provides a worldwide service organization with capable experts. The customers can select from a wide range of offers corresponding to their tailored solutions – clean, easy and safe!

Read more

Gas and dust measurement: limiting explosions

Norcem cement plant: Measuring dust at its best

New field: SICK reduces process costs for one of the world’s largest fertilizer manufacturers

Who analyzes wins